To train your staff like pros, focus on understanding all the machine’s components, proper cleaning, and maintenance routines. Teach them how to prepare, freeze, and serve ice cream efficiently while monitoring temperatures for quality. Recognize early signs of issues and troubleshoot effectively. Emphasize hygiene and safety standards through ongoing training, and perform regular quality checks. Keep improving skills continually—there’s always more to mastering ice cream machine best practices.

Key Takeaways

- Provide comprehensive training on equipment components, maintenance, and troubleshooting to ensure staff can operate and maintain machines effectively.

- Emphasize proper mixture preparation, temperature control, and freezing techniques for consistent ice cream quality.

- Implement strict cleaning, sanitation, and hygiene protocols to prevent contamination and extend equipment lifespan.

- Conduct regular quality checks during service to monitor texture, temperature, and cleanliness, ensuring customer satisfaction.

- Promote ongoing education and skill development to foster a culture of excellence and adaptability among staff.

Understanding Your Ice Cream Machine: Key Components and Functions

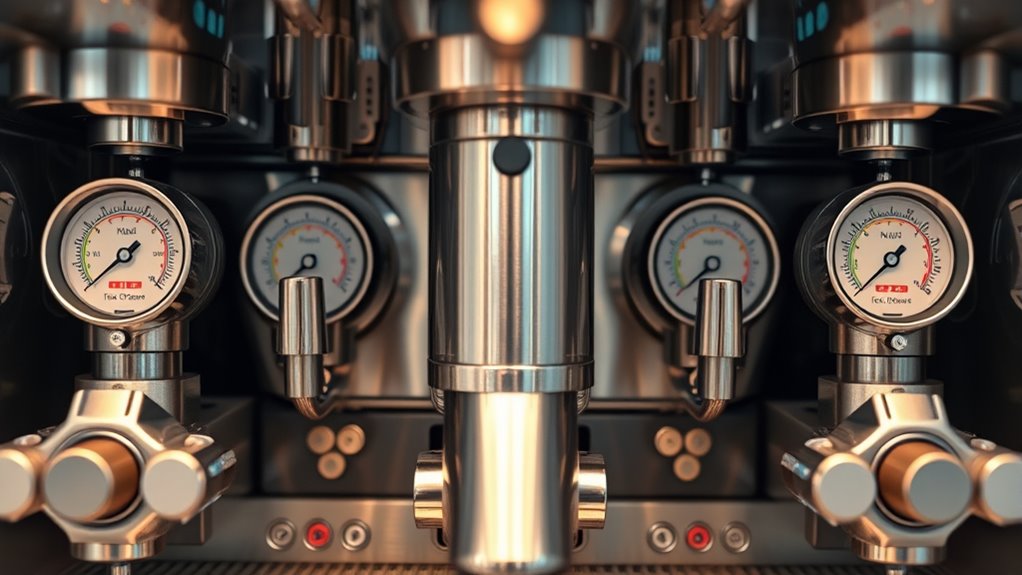

To effectively train your staff on operating the ice cream machine, you need to understand its key components and functions. The machine typically includes the compressor, freezing cylinder, dasher, and control panel. The compressor cools the mixture, while the dasher stirs it to create smooth, creamy ice cream. The control panel allows you to adjust settings based on the ice cream flavors you’re serving and customer preferences. Knowing how each part works helps staff troubleshoot issues quickly and ensures consistent quality. Recognizing how to select appropriate settings for different flavors ensures the ice cream maintains the right texture and temperature. This understanding empowers your team to deliver the best customer experiences and adapt to various flavor requests efficiently. Additionally, understanding the importance of proper maintenance and cleaning can prolong the lifespan of your equipment and ensure optimal performance. Regular monitoring of market trends can also help in scheduling timely upgrades or repairs, minimizing downtime. Being aware of appliance connection options can also facilitate quick replacements or repairs if needed, minimizing downtime. Familiarity with pimple patch technology can guide you in selecting the best products for your needs, ensuring effective customer recommendations. Moreover, staying informed about juice cleansing techniques and benefits can be useful if you’re considering offering health-conscious options alongside your ice cream products.

Proper Cleaning and Sanitizing Procedures

Keeping your equipment clean is essential for safety and quality. Follow a daily cleaning checklist to make certain no step gets skipped, and use proper sanitizing techniques to eliminate germs effectively. When staff understands these procedures, your operation runs smoother and stays compliant. Additionally, incorporating deep cleaning techniques for specific brands can help maintain optimal performance over time. Regular maintenance, including interior upgrades, ensures all components function properly and extends the lifespan of your equipment. Understanding filtration technologies can also guide you in adopting the most effective cleaning practices.

Daily Cleaning Checklist

Implementing a daily cleaning checklist guarantees your staff consistently follows proper cleaning and sanitizing procedures. Start each day by inspecting the ice cream machine, paying special attention to areas where ice cream flavoring is added, as residue can harbor bacteria. Make certain all components are thoroughly cleaned to prevent flavor cross-contamination and maintain product quality. Incorporate customer service techniques by reminding staff to communicate cleaning routines to customers, emphasizing hygiene standards. A clear checklist helps staff stay organized, reducing forgetfulness and ensuring no step is skipped. Regularly documenting completed tasks also promotes accountability. Additionally, understanding the importance of food safety practices is essential to prevent contamination and ensure customer health. Proper maintenance, such as filter cleaning and replacement, is vital for the overall performance of equipment. Maintaining consistent cleaning routines enhances hygiene standards, which are crucial for customer trust and satisfaction. Ensuring that staff are trained in proper equipment handling can further reduce the risk of contamination and prolong the lifespan of your machines. By establishing this routine, you create a clean environment, improve ice cream flavoring consistency, and boost customer confidence in your establishment’s hygiene practices.

Proper Sanitizing Techniques

Are you confident that your staff is using the most effective sanitizing techniques? Proper sanitizing is essential for maintaining equipment longevity and ensuring customer satisfaction. Make sure your team thoroughly cleans all parts of the ice cream machine with approved sanitizers after each use. Focus on reaching all nooks, crevices, and hard-to-clean areas to prevent residue buildup. Use the correct concentrations and follow manufacturer guidelines to avoid damaging equipment or compromising hygiene. Proper sanitizing not only reduces the risk of contamination but also extends the life of your machine, saving money in the long run. Additionally, understanding the importance of filtration systems can help in ensuring that your cleaning procedures are thorough enough to maintain the visual quality of your display or signage. Regular monitoring tools can assist in verifying that sanitation procedures are consistently effective. Implementing training programs that emphasize proper techniques can further enhance the effectiveness of your sanitation routines. Consistent, effective sanitizing practices demonstrate your commitment to quality, boosting customer confidence and loyalty. Recognizing patterns such as repeated sequences or specific numbers can serve as angel number signs that reinforce the importance of diligent hygiene practices.

Correctly Preparing and Freezing the Mixture

To guarantee your mixture freezes perfectly, you need to pay attention to its consistency, making sure it’s neither too thick nor too thin. Using proper freezing techniques helps maintain quality and prevents ice crystals from forming. Keeping an eye on temperature control is essential to preserve freshness and achieve the best results. Additionally, understanding best practices for frozen mixtures can further enhance the texture and flavor of your ice cream.

Mix Consistency Matters

Achieving the perfect mix consistency is essential for delivering quality products consistently. You want a smooth, uniform mix that ensures a desirable mix texture and reliable flavor consistency. If your mixture is too thick or too thin, it can lead to poor freezing results and inconsistent quality. To avoid this, measure ingredients carefully and blend thoroughly until the mixture is well combined. Pay attention to the viscosity—aim for a creamy, pourable consistency without lumps. Regularly check and adjust the mixture as needed before freezing. Properly prepared mixtures will freeze evenly, producing ice cream with the right texture and flavor every time. Monitoring mixture viscosity helps maintain optimal consistency and prevents issues during freezing. Consistent mixing techniques save time and reduce waste, helping your staff produce top-quality ice cream consistently. Additionally, understanding the essential oils for mix preservation can assist in maintaining freshness and preventing spoilage during storage. Implementing self-reflection techniques can also help staff identify areas for improvement in the mixing process, ensuring continuous quality enhancement.

Proper Freezing Techniques

Once your mixture is properly prepared and has the right consistency, the next step is to freeze it correctly to guarantee ideal texture and flavor. Proper freezing involves more than just placing the container in the freezer; it requires attention to freezer maintenance and ensuring the mixture cools evenly. To achieve excellent results, consider these tips:

- Use shallow containers for faster, uniform freezing

- Avoid overfilling to prevent uneven freezing

- Regularly check and maintain freezer temperature

- Label batches with date for freshness control

- Incorporate proper Porsche Tuning techniques to optimize the cooling process and prevent damage to the mixture. Additionally, understanding freezer temperature stability is crucial for maintaining consistent quality and preventing unwanted ice crystal formation. Ensuring the freezer is free of frost and operates efficiently can significantly impact the indoor air quality, which is vital for preserving the mixture’s integrity. Proper freezing helps prevent ice crystal formation and preserves creaminess. Consistent freezer maintenance ensures the temperature stays stable, avoiding fluctuations that can ruin the texture. Implementing these practices ensures your ice cream maintains quality from start to finish.

Temperature Control Essentials

Proper temperature regulation is crucial when preparing and freezing your mixture because it directly impacts texture, flavor, and overall quality. Maintaining the right temperature ensures your ice cream achieves consistent flavor and smooth texture, boosting customer satisfaction. Use a thermometer to monitor the mixture as you cool and freeze it, aiming for around 4°C (39°F) before churning. Freezing too quickly or slowly can cause ice crystal formation, affecting flavor and texture. Keep the mixture at a steady temperature during the process to ensure flavor consistency. Remember, rapid freezing preserves quality, while fluctuations lead to undesirable changes. To help visualize, here’s a quick overview:

| Step | Temperature Range | Key Focus |

|---|---|---|

| Cooling | 4°C (39°F) | Flavor preservation |

| Freezing | -20°C (-4°F) | Texture consistency |

| Storage | -18°C (0°F) | Quality retention |

| Serving | -15°C to -20°C | Ideal texture |

Mastering the Loading and Dispensing Techniques

Mastering loading and dispensing techniques is essential for maintaining accuracy and efficiency in your staff’s daily operations. Proper methods guarantee consistent product quality, which boosts customer feedback and satisfaction. To motivate staff, demonstrate precise techniques and encourage attention to detail. Focus on these key practices:

- Use the correct scoop size for consistent portions

- Keep the machine clean to prevent contamination

- Avoid overfilling to reduce waste and mess

- Train staff to identify signs of machine issues early

Recognizing and Troubleshooting Common Machine Issues

Knowing how to recognize common machine problems is essential for keeping operations smooth. When issues arise, following effective troubleshooting steps can save time and prevent damage. Let’s explore the key problems to watch for and how to address them quickly.

Identifying Common Problems

Recognizing common machine problems early can save you time and prevent costly breakdowns. Regularly inspecting your ice cream machine helps identify issues before they escalate, especially during busy hours. Look for signs like inconsistent texture, unusual noises, or longer freeze times. Poor staff scheduling can lead to rushed cleaning or maintenance, increasing the risk of problems. Staying on top of equipment upgrades ensures your machine runs smoothly and reduces frequent malfunctions. Keep an eye out for leaks, ice buildup, or temperature fluctuations. Training staff to spot these early signs allows for quick action, minimizing downtime. Consistent monitoring and proactive maintenance, combined with proper staff scheduling, keep your equipment reliable and your service seamless.

Effective Troubleshooting Steps

When issues with your ice cream machine arise, quick and effective troubleshooting can prevent costly repairs and downtime. Start by checking the machine calibration to ensure temperatures and mix consistency are correct. If the machine isn’t operating properly, communicate clearly with your staff to gather details about symptoms and recent changes. Proper staff communication helps identify whether the problem is mechanical, electrical, or related to input quality. Always follow a systematic troubleshooting process: verify calibration settings, inspect for blockages or leaks, and listen for unusual noises. If issues persist, document the problem and escalate it to maintenance or a technician. Training staff to recognize early signs and communicate effectively streamlines troubleshooting, saving time and reducing the risk of more significant breakdowns.

Maintaining Consistent Serving Temperatures

Maintaining consistent serving temperatures is essential for delivering the best customer experience and ensuring food safety. Proper temperature calibration helps keep your ice cream at the ideal state, preserving its smoothness and flavor. When temperatures fluctuate, ice cream can become too soft or hard, affecting ice cream consistency and customer satisfaction. Regularly check and calibrate your machine’s thermostat to avoid these issues. Additionally, monitor storage and serving areas to prevent temperature swings. Keep these practices in mind:

- Perform routine temperature calibration checks

- Maintain a stable environment around the machine

- Use accurate thermometers for readings

- Adjust settings promptly if temperature deviations occur

Monitoring and Managing Machine Hygiene and Maintenance

Consistent temperature control relies heavily on good machine hygiene and regular maintenance. You need motivated staff who understand the importance of cleaning schedules and routine checks to prevent buildup and contamination. Encourage your team by highlighting how proper hygiene directly impacts product quality and customer satisfaction. Regular maintenance, including equipment upgrades when necessary, keeps the machine running smoothly and reduces downtime. Implement a clear schedule for cleaning and inspections, and hold staff accountable through positive reinforcement. When staff see the benefits of a well-maintained machine—fewer breakdowns and better ice cream quality—they stay motivated. Upgrading equipment periodically can also improve hygiene standards and efficiency. Staying proactive in monitoring and managing hygiene is essential for consistent performance and happy customers.

Training Staff on Safety and Hygiene Standards

Effective training on safety and hygiene standards is essential for ensuring your staff consistently follow proper procedures. When your team understands the importance of cleanliness and safety, they’re more motivated to maintain high standards. To foster this, focus on engaging staff with clear protocols and explain how their actions impact customer feedback. You can boost staff motivation by highlighting their role in creating a safe environment and satisfied customers. Incorporate practical demonstrations, regular refreshers, and accountability checks. Consider these key points:

- Reinforce proper handwashing and glove use

- Emphasize cleaning schedules and sanitation procedures

- Train staff to identify and address safety hazards

- Encourage open communication about hygiene concerns

This approach keeps safety top of mind and improves overall service quality.

Implementing Quality Control Checks During Service

Implementing quality control checks during service is essential for maintaining high standards and promptly addressing issues. Regular checks ensure your staff upholds quality assurance by consistently monitoring ice cream consistency, temperature, and cleanliness. These checks help catch problems early, preventing subpar product from reaching customers. By establishing clear protocols, you assign staff accountability, making everyone responsible for maintaining standards. Encourage your team to perform quick visual inspections and taste tests at set intervals, documenting any irregularities. This proactive approach keeps the operation smooth and ensures customer satisfaction. Consistent quality control reinforces the importance of adhering to best practices, fostering a culture of excellence. Ultimately, these measures help you deliver a first-rate product while empowering your staff to take ownership of their service quality.

Continual Education and Skill Development for Staff

To keep your staff performing at their best, prioritizing continual education and skill development is essential. Motivational coaching boosts confidence, encouraging staff to improve their skills and stay engaged. Regular training sessions reinforce proper ice cream machine maintenance and troubleshooting techniques. Effective team communication helps identify knowledge gaps and fosters collaboration. Consider these strategies:

- Implement ongoing workshops that focus on new equipment features

- Use motivational coaching to recognize progress and motivate improvement

- Schedule team debriefs to discuss challenges and share solutions

- Encourage cross-training to diversify skills and increase flexibility

Frequently Asked Questions

How Often Should Ice Cream Machines Be Professionally Serviced?

You should schedule professional maintenance for your ice cream machines at least every three to six months. Following a proper maintenance schedule helps prevent breakdowns and guarantees quality. Make sure your technician has the right qualifications and experience to handle your specific model. Regular servicing by qualified professionals assures your machines stay in top condition, reducing downtime and extending their lifespan. Stay proactive to keep your ice cream operations running smoothly.

What Are the Best Ways to Handle Machine Downtime Efficiently?

Think of your ice cream machine as a well-tuned orchestra; when one instrument falters, the whole performance suffers. To handle downtime efficiently, implement preventative maintenance and quick troubleshooting techniques. Regular checks catch issues early, minimizing disruptions. Keep a troubleshooting guide handy, and train staff to recognize common problems. This proactive approach guarantees smooth operations, reduces lost sales, and keeps your “orchestra” performing beautifully, even when unexpected issues arise.

How Can I Train Staff to Identify Subtle Machine Malfunctions?

To train your staff to identify subtle machine malfunctions, you need to emphasize sensor calibration and visual inspections. Show them how to regularly check sensors for proper functioning and calibration to catch issues early. Teach them to perform visual inspections for leaks, unusual noises, or wear. Encourage proactive monitoring, so they can spot problems before they escalate, ensuring smooth operation and reducing downtime.

What Safety Gear Is Recommended During Machine Cleaning?

When cleaning ice cream machines, you should always wear protective gloves to prevent contact with cleaning chemicals and guarantee hygiene. Eye protection is also essential to guard against splashes or sprays of cleaning solutions. These safety gear items help you avoid injuries and cross-contamination. Always follow your workplace safety protocols, and remind your staff to use protective gloves and eye protection consistently during all cleaning procedures.

How Do Seasonal Changes Affect Ice Cream Machine Performance?

Seasonal temperature changes and ingredient variability can profoundly impact your ice cream machine’s performance. As temperatures rise or fall, your machine may struggle to maintain ideal freezing or consistency. You should regularly adjust your refrigeration settings and monitor ingredient quality to guarantee smooth operation. By staying attentive to seasonal shifts, you’ll prevent issues like inconsistent texture or overworking the machine, keeping your ice cream delicious and your equipment running efficiently.

Conclusion

Think of mastering ice cream machine operation as tending a delicate garden; each task from cleaning to troubleshooting nurtures its health. When you stay attentive and proactive, your machine blooms with perfect treats, delighting every guest. Like a seasoned gardener, your dedication ensures vibrant, flawless results. Keep learning and refining your skills—your effort transforms a simple machine into a masterpiece of frozen delight. In this way, you cultivate not just ice cream, but excellence.