If your ice cream machine isn’t working properly, start by inspecting and cleaning all components like blades, paddles, and nozzles to remove buildup. Make sure the machine is level and placed away from heat or sunlight for ideal cooling. Check for leaks or spillages, tighten fittings, and reset the system if needed. For persistent problems, consider professional repairs to prevent further damage—keep going to discover more helpful tips.

Key Takeaways

- Regularly inspect and clean blades, paddles, nozzles, and internal parts to prevent buildup and ensure quality.

- Ensure proper installation on a level surface and maintain good airflow for optimal cooling performance.

- Check hoses, seals, and drip trays for leaks or blockages; reset the machine by unplugging and waiting before restarting.

- Listen for unusual noises or vibrations indicating mechanical issues; address problems promptly to prevent further damage.

- For complex electrical or mechanical faults, contact professional technicians to ensure safe and effective repairs.

Checking and Cleaning the Machine Components

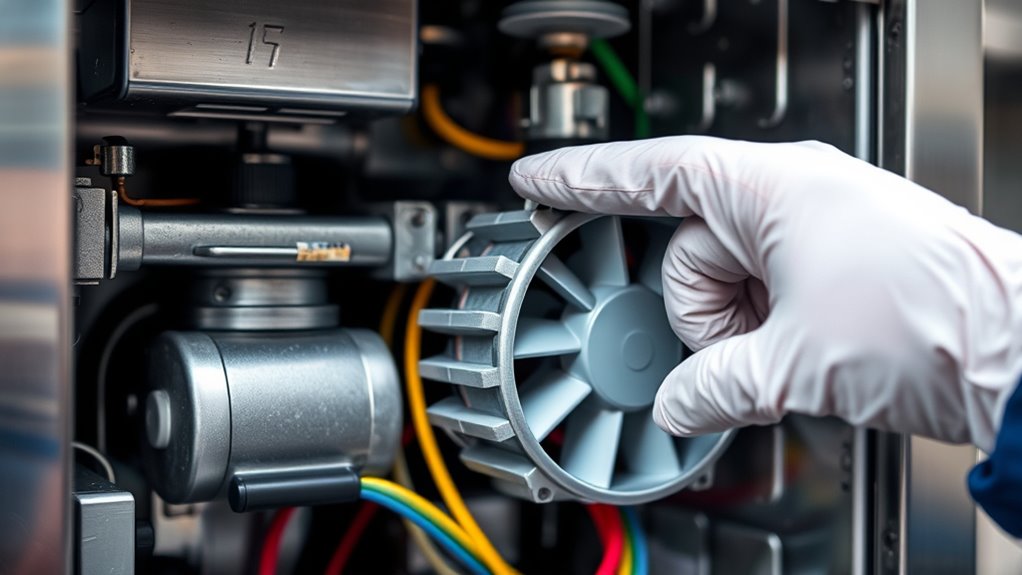

Regularly checking and cleaning the machine components is essential to keep your ice cream machine running smoothly. Start by inspecting the blades, paddles, and nozzles for any buildup or residue that could affect ingredient quality. Clean these parts thoroughly to prevent contamination and ensure consistent texture. Pay attention to storage conditions for ingredients; improper storage can lead to spoilage or clumping, which impacts your final product. Use warm, soapy water and a brush to remove any leftover ice cream or debris. Rinse all parts well to avoid soap residue that could alter taste. Proper cleaning and storage are your first line of defense against common machine issues. Additionally, understanding the benefits of regular maintenance can help extend the lifespan of your equipment and maintain optimal performance. Implementing preventative measures can further reduce the likelihood of breakdowns and costly repairs. Regular inspections and timely replacements of worn parts also contribute to machine longevity and dependable operation. Incorporating proper sanitation procedures is crucial for maintaining hygiene standards and preventing bacterial growth.

Ensuring Proper Installation and Level Placement

Proper installation and level placement are crucial for your ice cream machine to operate efficiently. Follow these installation tips to guarantee peak performance and longevity. First, position the machine on a flat, stable surface, avoiding uneven or soft flooring. Use a level to check that the unit sits perfectly horizontal; an uneven placement can cause uneven cooling or mechanical strain. Adhere to placement guidelines by keeping the machine away from direct sunlight, heat sources, and high-traffic areas to prevent overheating or accidental damage. Ensure proper ventilation around the unit, allowing air to circulate freely. Secure all connections and power cords to prevent movement. Correct installation and careful placement help prevent common issues and make maintenance easier, keeping your ice cream machine running smoothly. Additionally, market growth projections indicate that proper setup is essential to avoid costly repairs as technology advances, emphasizing the importance of proper equipment installation for long-term success. Maintaining precise level placement is also vital, as even slight inclinations can affect the internal mechanisms and cooling efficiency. Regularly checking the installation environment and ensuring adequate air circulation helps sustain optimal performance over time.

Troubleshooting Freezing and Cooling Issues

Even with correct installation and placement, your ice cream machine can still face freezing and cooling issues. If the texture is too soft or ice crystals form, the problem might stem from inadequate temperature control or poor insulation. Check that the compressor is functioning properly and that the thermostat is set correctly. Proper container insulation helps maintain consistent cooling, which is essential for flavor preservation. To illustrate, consider this:

| Insulation Type | Effect on Cooling | Impact on Flavor Preservation |

|---|---|---|

| Foam | Good | Keeps flavors fresh |

| Gel | Moderate | Slight risk of flavor loss |

| No insulation | Poor | Flavors deteriorate |

Ensuring adequate insulation and proper temperature settings keeps your ice cream consistently delicious. Additionally, reviewing air circulation within the unit can prevent uneven cooling and improve overall performance. Proper ventilation plays a crucial role in maintaining optimal cooling efficiency and preventing overheating of components. Furthermore, regular cleaning of cooling systems can prevent build-up that impairs cooling performance. Maintaining proper airflow management can also extend the lifespan of your machine and ensure consistent results.

Addressing Leaks and Spillages

Are leaks and spillages disrupting your ice cream machine’s operation? Check the drip tray first; a full or improperly positioned tray can cause overflow. Regularly empty and clean it to prevent spillages and guarantee spill prevention. Inspect hoses and connections for cracks or loose fittings, as these often cause leaks. Tighten or replace damaged parts promptly. If you notice ice build-up around seals, thaw and clean those areas to maintain a proper seal. Use a damp cloth to wipe away any excess drips or spills immediately, preventing messes from spreading. Proper maintenance of the drip tray and sealing components is key to avoiding leaks. Additionally, ensuring your machine’s filtration system is functioning properly helps prevent debris buildup that could contribute to leaks. Regularly checking for noise levels of your equipment can also alert you to potential issues before leaks develop. Staying vigilant about spill prevention and understanding Kia Tuning options can help optimize your machine’s performance and longevity, keeping your workspace clean and safe. Properly calibrating your machine’s temperature settings can also reduce the risk of leaks caused by overworking components. Utilizing filter maintenance routines can further enhance the longevity of your equipment and prevent clogs that may lead to leaks.

Resetting and Power Cycling Your Device

Sometimes, simply resetting or power cycling your ice cream machine can resolve minor glitches and restore normal operation. To do this, turn off the machine and unplug it from the power source. Wait about 30 seconds to guarantee all internal components reset. Power cycling can clear temporary bugs that cause issues like freezing or unresponsive controls. Plug it back in and turn it on. During this process, check the user interface for any error messages or irregularities. If your device recently received a software update, restarting it can help apply the changes properly. If problems persist after this step, consult the user manual for specific reset instructions or consider updating the software if an update is available. This simple step often gets your machine back to working smoothly. Additionally, performing a system reset or software refresh can sometimes be necessary for more persistent issues. Regularly maintenance procedures can also help prevent future problems and keep your device running efficiently. Remember that understanding factors affecting device performance can help you troubleshoot more effectively in the long run.

When to Seek Professional Repairs

If your ice cream machine keeps experiencing mechanical failures or electrical issues, it’s time to call in a professional. Unusual noises that don’t stop or worsen also signal that expert help is needed. Addressing these signs early can prevent further damage and costly repairs. Additionally, if you notice persistent clogs or leaks, seeking professional assistance can help diagnose underlying problems that might not be immediately apparent. Recognizing early warning signs can save you time and money in the long run.

Persistent Mechanical Failures

Persistent mechanical failures in your ice cream machine can be frustrating, especially when simple troubleshooting doesn’t resolve the issue. If your machine consistently jams, leaks, or fails to churn properly despite checking the basics, it’s time to think about professional repairs. These failures often stem from worn-out parts or internal damage that requires expert attention. While experimenting with different ice cream recipes and flavor combinations can be fun, persistent mechanical issues hinder your creativity. Don’t risk further damage or voiding warranties by attempting complex repairs yourself. Instead, contact a qualified technician who can diagnose and fix the problem efficiently. Proper repairs ensure your machine runs smoothly, so you can keep creating delicious ice creams without interruption.

Electrical Issues Detected

Electrical issues in your ice cream machine can be tricky to identify and resolve on your own. If you notice inconsistent power supply or the machine won’t turn on, it’s time to contemplate professional help. Before calling a technician, check the wiring connections for loose or damaged wires. Confirm the power cord is properly plugged in and the outlet functions correctly. Look for any signs of burnt components or blown fuses that could disrupt the power supply. If you experience frequent tripping of circuit breakers or if the machine still doesn’t operate after basic checks, it’s best to seek professional repairs. Remember, electrical components can be dangerous, so avoid attempting complex fixes yourself. When in doubt, call a qualified technician to diagnose and repair your ice cream machine safely.

Unusual Noises Occur

Unusual noises coming from your ice cream machine often signal that something’s wrong inside, and ignoring these sounds can lead to more serious damage. If you notice strange sound vibrations or increased motor noise, it’s a sign that a component may be malfunctioning or loose. Persistent rattling, grinding, or squealing aren’t normal and should be addressed promptly. These noises could indicate worn belts, debris caught in moving parts, or motor issues. Continuing to use the machine without inspection can cause further damage, leading to costly repairs. When you hear unusual sounds, it’s best to turn off the machine and seek professional repair services. A trained technician can diagnose the problem accurately and ensure your ice cream machine runs smoothly again.

Frequently Asked Questions

How Often Should I Perform Maintenance on My Ice Cream Machine?

You should perform maintenance on your ice cream machine regularly to keep it running smoothly. Aim to check the machine calibration monthly to guarantee peak performance. Follow a consistent cleaning schedule—ideally after each use or at least daily—to prevent buildup and bacteria growth. Regular maintenance helps extend your machine’s lifespan and ensures high-quality ice cream. Don’t wait until issues arise; proactive care keeps your machine in top shape.

Can I Use Household Cleaners for Cleaning the Machine Components?

You shouldn’t use household cleaners or household products on your ice cream machine components. These cleaning agents aren’t designed for food equipment and can leave harmful residues. Instead, use cleaning solutions recommended by the manufacturer to guarantee safety and proper cleaning. Always rinse thoroughly after cleaning with any approved cleaning agents, and avoid using harsh household products that could damage the machine or affect the taste of your ice cream.

What Are the Signs That My Machine Needs Professional Repair?

When your machine makes loud noise, produces inconsistent texture, or struggles to churn properly, it’s time to call in a professional. These signs indicate issues beyond simple cleaning or adjustments, like worn components or electrical problems. Don’t ignore persistent machine noise, erratic operation, or texture inconsistencies. Addressing these early can prevent costly repairs later. Trust a professional to diagnose, troubleshoot, and fix your ice cream machine efficiently.

How Do I Prevent Ice Buildup Inside the Machine?

To prevent ice buildup inside your machine, you should regularly check and maintain proper refrigeration efficiency. Keep the door seals clean and ensure they close tightly to minimize moisture entry. Also, defrost the machine as needed and avoid overfilling, which can cause excess condensation. Good hygiene helps mold prevention, which can also contribute to ice buildup. Consistent maintenance keeps your machine running smoothly and extends its lifespan.

Is It Safe to Operate the Machine During a Power Outage?

Think of your ice cream machine as a delicate dance partner; operating it during a power outage is like forcing a dance in the dark. For power outage safety, avoid running the machine when power is lost, as it can damage internal parts or cause safety hazards. Wait until power is restored before resuming machine operation. Protect your equipment and guarantee safe, smooth operation by following these simple precautions.

Conclusion

So, after all that troubleshooting, you’d think your ice cream machine would be smooth sailing. But if it still refuses to churn or keeps leaking, maybe it’s time to call in the pros. Irony’s on your side—sometimes fixing things yourself isn’t enough, and your machine’s stubbornness reminds you that even the simplest gadgets can outsmart us. Until then, enjoy the effort—and maybe a bowl of store-bought ice cream instead!