If your ice cream machine suddenly malfunctions, immediately check the power supply and reset the machine by unplugging it briefly, then plugging it back in. Look for any error codes and follow the manual to troubleshoot specific issues. Make certain the machine is clean, fluids are at proper levels, and mechanical parts are damage-free. If the problem persists, contacting support is wise. Continuing further will help you handle the emergency confidently.

Key Takeaways

- Unplug and reset the machine to clear temporary errors or glitches.

- Check for error codes and consult the manual for specific troubleshooting steps.

- Ensure power outlets and connections are safe, stable, and not overloaded.

- Inspect for residue buildup, leaks, or mechanical damage, and clean or repair as needed.

- Contact technical support if the issue persists after basic troubleshooting.

Check the Power Supply and Reset the Machine

If your ice cream machine isn’t working properly, the first step is to check the power supply. Power fluctuations can cause your machine to malfunction or shut down unexpectedly. Confirm the outlet you’re using is safe by inspecting for damage or loose connections. Avoid plugging the machine into overloaded outlets or extension cords, which can lead to unstable power delivery. After verifying outlet safety, reset the machine by turning it off, unplugging it, and waiting a few minutes. This reset can clear minor electrical glitches. Once you’ve done that, plug it back in and turn it on. If issues persist, double-check the circuit breaker to see if it’s tripped, and reset it if necessary. Proper power supply management is essential for reliable operation. Additionally, ensuring the power supply provides consistent voltage helps prevent damage and maintains optimal performance. To further safeguard your equipment, consider using a voltage stabilizer to protect against power surges. Regularly inspecting the electrical connections can also prevent potential malfunctions and extend the lifespan of your appliance. Incorporating proper maintenance routines can help identify issues before they cause operational failures, especially since sound vibrations from electrical components can sometimes indicate underlying problems.

Inspect the Error Codes and Troubleshoot Accordingly

When your ice cream machine shows an error code, start by decoding the message to understand the issue. Refer to the user manual for specific troubleshooting steps related to that code. After addressing the problem, make sure to reset the machine properly to resume operation smoothly. Additionally, ensure your equipment is regularly maintained to prevent future malfunctions and monitor system performance for early detection of issues. Implementing preventive maintenance strategies can help in reducing unexpected failures and prolonging equipment lifespan. Being aware of regulatory compliance requirements can also help prevent legal complications related to equipment operation. Incorporating data-driven strategies can further optimize your maintenance routines and prevent unexpected failures. Regularly reviewing performance data can help identify patterns and potential issues before they escalate.

Decode Error Messages

Error messages on your ice cream machine serve as vital clues to identify the underlying issues. When you see an error code, don’t ignore it—use it to guide your troubleshooting tips safely. First, note the specific code displayed; this helps determine the problem quickly. Second, consult the safety precautions to avoid electrical hazards or damage during inspection. Third, look up the error code in your manual or manufacturer’s website, focusing on recommended fixes. Remember, decoding these messages correctly can save you time and prevent further damage. Always prioritize safety when troubleshooting, and if you’re unsure, contact a professional. Taking these steps ensures you address the problem efficiently without risking safety or causing more issues. Understanding error code interpretation can significantly improve your troubleshooting effectiveness, especially as modern appliances become more integrated with AI safety features that monitor for errors and malfunctions. Additionally, familiarizing yourself with common component failures can help you diagnose issues more accurately and expedite repairs. For example, knowing how different electrical components typically fail can help you pinpoint problems faster and reduce downtime. Regularly inspecting the pump and motor parts can also prevent unexpected breakdowns and prolong the lifespan of your machine.

Refer to User Manual

Have you checked your user manual when an error code appears on your ice cream machine? Your manual is a crucial resource for understanding what the error means and how to address it safely. It provides specific troubleshooting steps tailored to your machine’s model, ensuring you don’t compromise ice cream safety or damage the equipment. Pay close attention to error codes and their descriptions, which often indicate issues like temperature faults or component mismatches. Knowing your machine’s appliance connection with certain parts or ingredients can prevent further problems. Regular maintenance and understanding error diagnostics can help you identify issues early and avoid costly repairs. Familiarizing yourself with machine specifications outlined in the manual allows for more accurate troubleshooting. Always follow the manual’s guidance to troubleshoot effectively and avoid voiding warranties. Referencing the manual ensures you take the right steps quickly, minimizing downtime and ensuring your machine operates safely and efficiently. Recognizing common troubleshooting steps can empower you to resolve minor issues without professional help. Additionally, understanding celebrity lifestyle insights related to appliance use can sometimes provide useful tips for household appliances in entertainment settings.

Reset Machine Properly

Before attempting to reset your ice cream machine, it’s vital to carefully inspect the error codes displayed. It helps to consult the user manual or on-screen display to understand what each code indicates about the specific issue. It guides you to the root problem. Understanding credit card terms is also important if you plan to make repairs or purchase replacement parts, ensuring you’re aware of warranty conditions and service costs. Inspect for blockages or leaks that may affect the machine’s operation, especially if certain flavors aren’t dispensing properly. Security measures are crucial when dealing with electronic components to prevent data breaches or damage. Verify the power supply and connections to ensure consistent operation, especially since electric components are involved. Properly troubleshooting guarantees you don’t cause further damage. Additionally, understanding the self-watering plant pots can help you maintain your indoor garden effectively, which may be useful if you want to keep fresh herbs or plants nearby while troubleshooting your appliance. Recognizing cybersecurity vulnerabilities related to connected devices can help protect your home network during repairs. Being aware of the Kia Tuning options can also help if you need to ensure your vehicle’s electronic systems are functioning correctly post-repair, especially since modern appliances and vehicles often share similar electronic troubleshooting principles. Here’s how to proceed:

Ensure Proper Cleaning and Maintenance

To keep your ice cream machine running smoothly, you need to follow a regular cleaning schedule. Make sure you use the right cleaning products to avoid residue buildup that can cause issues. Regular inspections will help you catch any residue or deposits before they become bigger problems.

Regular Cleaning Schedule

Maintaining a regular cleaning schedule is essential to keep your ice cream machine functioning smoothly and to prevent breakdowns. A consistent cleaning routine helps remove residue and prevents bacteria buildup, ensuring the machine operates efficiently. To stay on top of this, consider these key steps:

- Set specific days and times for cleaning to create a reliable maintenance schedule.

- Thoroughly clean all removable parts, including nozzles and containers, after each use.

- Sanitize the entire machine regularly to eliminate germs and prevent mold growth.

Use Proper Cleaning Products

Using the right cleaning products is essential for effectively removing residue and preventing damage to your ice cream machine. Choose cleaning supplies specifically designed for ice cream machines or food equipment to avoid corrosion or buildup. Regular dish soap may not be enough; instead, use industry-approved sanitization methods and solutions to ensure thorough cleanliness. Make sure your cleaning supplies are food-safe and compatible with your machine’s materials. Proper cleaning products help break down dairy residues and prevent bacteria growth, ensuring safety and superior performance. Always follow the manufacturer’s instructions for dilution and contact time. Using inappropriate cleaners can cause damage or leave harmful residues. Prioritize quality cleaning supplies to maintain your machine’s longevity and ensure your ice cream remains safe and delicious.

Inspect for Residue Buildup

Have you checked your ice cream machine for residue buildup lately? Residue buildup can cause malfunctions and affect the quality of your ice cream. To prevent issues, inspect key areas during cleaning procedures.

- Look inside the freezing chamber and around the dasher for any sticky or hardened residue.

- Check the hopper and chute for leftover ice cream or debris that may hinder operation.

- Examine seals and gaskets for buildup that could cause leaks or contamination.

Regularly inspecting these spots helps you catch residue buildup early, ensuring your cleaning procedures keep the machine in top shape. Removing residue buildup promptly maintains hygiene, prevents breakdowns, and prolongs your machine’s lifespan. Don’t skip these steps—your ice cream machine relies on thorough inspections.

Verify Fluid Levels and Quality

Is your ice cream machine’s fluid levels where they should be? If not, perform a quick fluid check to ensure proper operation. Low fluid levels can cause overheating or inconsistent ice cream texture. Carefully inspect the reservoirs or tanks, looking for any signs of leaks or evaporation. Next, do a quality assessment of the fluid—check for discoloration, cloudiness, or any unusual odors. Dirty or degraded fluid can impair mixing and freezing performance. If the fluid appears contaminated or has been sitting too long, drain and replace it with fresh, manufacturer-approved fluids. Maintaining proper fluid levels and ensuring their quality are essential steps to keep your machine running smoothly and avoid emergencies. Regular checks can prevent costly repairs and downtime.

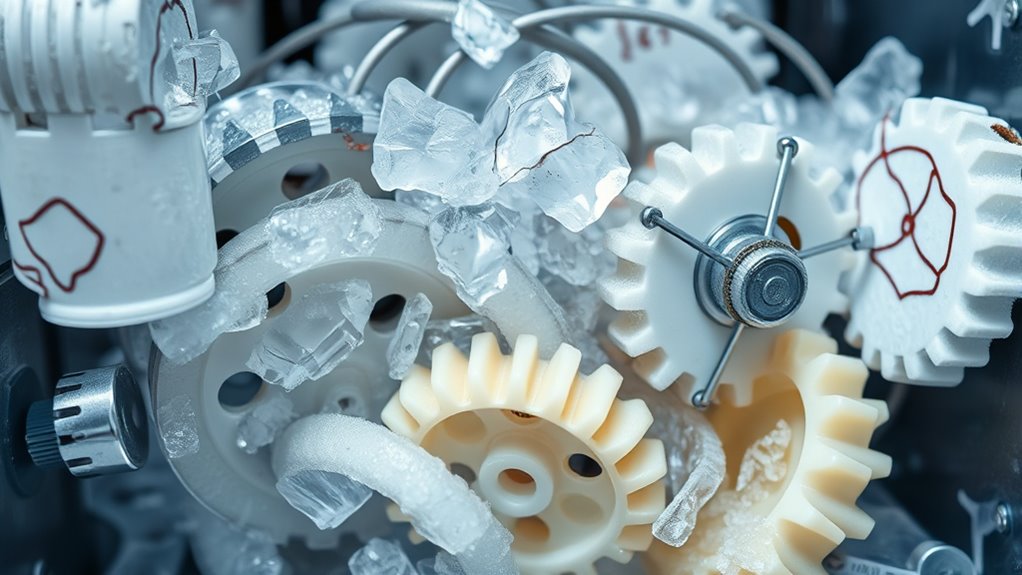

Examine Mechanical Components for Obstructions or Damage

Before operating your ice cream machine, it is crucial to inspect the mechanical components for any obstructions or damage. A thorough mechanical inspection helps identify issues that could cause a breakdown or safety hazards. Start by checking the drive belt for cracks or wear, as damaged belts can hinder proper operation. Next, examine the churning mechanism and blades for any signs of component damage or blockages that could impede the mixing process. Finally, inspect gears and motors for unusual sounds or signs of wear, which may indicate impending failure. Address any obstructions immediately and replace damaged parts before restarting the machine. Performing this mechanical inspection ensures your equipment runs smoothly and prevents costly repairs down the line. Remember, catching component damage early keeps your operation safe and efficient.

Assess Temperature Settings and Calibration

Ensuring your ice cream machine operates at the correct temperature begins with evaluating and calibrating its temperature settings. Start by checking the current temperature display and compare it to the ideal range specified in the user manual. If the temperature seems off, perform a temperature calibration. This process involves adjusting the sensor to guarantee it accurately reads the internal temperature. Locate the sensor adjustment screw or dial, usually accessible through the control panel or behind the machine’s panel. Make small, incremental adjustments, then test the temperature again. Proper sensor adjustment guarantees precise readings, preventing the machine from running too warm or too cold. Accurate temperature calibration is essential for consistent ice cream quality and preventing emergency issues caused by incorrect settings.

Contact Technical Support if Issue Persists

If troubleshooting the temperature and calibration steps doesn’t resolve the problem, it’s time to contact technical support. They can help diagnose issues beyond basic fixes, especially if preventative maintenance hasn’t been performed regularly. Before reaching out, ensure your staff has proper user training to operate the machine correctly. When you contact support, have details ready about your machine’s model, error messages, and recent maintenance history to speed up the process.

Contact support with machine details and error info if troubleshooting and maintenance don’t resolve issues.

Here are three steps to follow:

- Verify that all routine preventative maintenance has been completed.

- Document any error codes or unusual behaviors.

- Confirm staff training on proper operation and troubleshooting.

This approach helps ensure a quick resolution while minimizing downtime.

Frequently Asked Questions

How Often Should I Perform Routine Maintenance on My Ice Cream Machine?

You should perform routine maintenance on your ice cream machine regularly to keep it running smoothly. Follow a cleaning schedule daily or after each use, and use a detailed maintenance checklist weekly or monthly. This helps prevent breakdowns and guarantees hygiene. Consistent upkeep extends the machine’s lifespan, maintains product quality, and avoids costly repairs. Stay proactive with your maintenance routine to keep your machine in top condition.

What Safety Precautions Should I Take Before Troubleshooting?

Before troubleshooting, you should prioritize safety by wearing appropriate safety gear like gloves and goggles. Make sure to perform an electrical shutdown to prevent shocks or accidents. Check that the machine is unplugged and has cooled down if necessary. Keep your workspace dry and clear of hazards. These precautions guarantee your safety and help you troubleshoot efficiently without risking injury or damage to the equipment.

Can Environmental Factors Affect My Ice Cream Machine’S Performance?

Like a weather vane, your machine responds to its surroundings. Climate influence and storage conditions can sway its performance, making it sluggish or inconsistent. High humidity, extreme temperatures, or poor storage can clog parts or cause overheating. Keep your environment stable, cool, and dry to guarantee smooth operation. Regularly check and optimize storage conditions so your machine stays as dependable as a lighthouse guiding ships safely ashore.

Are There Specific Brands or Models More Prone to Emergencies?

When choosing an ice cream machine, consider brand susceptibility and model reliability. Some brands are known for higher failure rates, making them more prone to emergencies. Research reviews and customer feedback to identify models with solid reputations for durability and consistent performance. Investing in trusted brands and reliable models helps reduce unexpected breakdowns, ensuring your machine runs smoothly and minimizes downtime during busy hours.

What Signs Indicate My Machine Needs Professional Repair Instead of DIY Fixes?

When your machine starts to leak or makes odd noises, it’s a gentle nudge that professional repair might be needed. Don’t ignore persistent dripping or strange sounds, as they signal internal issues. If troubleshooting doesn’t resolve these signs, it’s best to call in an expert. Trying DIY fixes could worsen the problem, so trusting the pros guarantees your machine stays in top shape and avoids costly damage.

Conclusion

Did you know that nearly 60% of ice cream machine breakdowns can be prevented with regular maintenance? By checking the power, inspecting error codes, cleaning properly, and verifying fluid levels, you can often fix issues fast. If problems persist, don’t hesitate to call support. Acting quickly not only keeps your machine running smoothly but also saves you money in the long run. Stay proactive, and your ice cream will stay delicious and available whenever your customers crave it!