To extend your ice cream machine’s lifespan, keep it clean and sanitized regularly, disassembling parts to prevent bacteria buildup. Use high-quality ingredients and mix thoroughly for consistent results. Lubricate moving components with proper food-grade oil and check the refrigeration system often to maintain proper temperatures. Avoid overloading, replace worn parts promptly, and follow manufacturer guidelines. Proper maintenance and professional servicing help prevent costly repairs—continue exploring these tips to keep your machine running smoothly longer.

Key Takeaways

- Regularly clean and sanitize all removable parts and interior surfaces to prevent residue buildup and bacterial contamination.

- Maintain proper refrigerant levels and clean condenser coils frequently to ensure efficient cooling and prevent overheating.

- Follow a scheduled lubrication routine for moving parts using food-grade oils to reduce wear and extend equipment lifespan.

- Conduct routine performance assessments and calibrations with professional technicians to ensure optimal operation and product quality.

- Invest in timely professional servicing and upgrade accessories to improve durability, ease maintenance, and prolong machine life.

Regularly Clean and Sanitize Your Machine

To keep your ice cream machine running smoothly, you need to clean and sanitize it regularly. Establishing effective cleaning routines ensures that residue and bacteria don’t build up, which can affect taste and machine longevity. Use proper sanitization techniques by choosing food-safe cleaning solutions designed for dairy equipment. Start by disassembling removable parts and washing them thoroughly with warm, soapy water. Wipe down the interior surfaces with a sanitizing solution, making sure to reach all crevices. Rinse everything well to remove any cleaning residue. Regular cleaning not only prolongs your machine’s lifespan but also guarantees the safety and quality of your ice cream. Incorporate these routines into your maintenance schedule for consistent performance and hygiene. Additionally, air purifier maintenance can help eliminate airborne contaminants that may settle on your equipment, further protecting your product quality. Proper ventilation is essential to prevent excess moisture buildup, which can promote mold growth and compromise your machine’s condition. Monitoring machine performance regularly can also help identify potential issues early, ensuring longevity and optimal operation. Proper ventilation and refrigerant management are also essential to maintain an efficient and environmentally friendly cooling system in your equipment, and routinely inspecting cooling components can prevent unexpected breakdowns.

Use the Right Ingredients and Mix Properly

Using fresh, high-quality ingredients guarantees your ice cream tastes great and reduces strain on your machine. Make sure to mix everything thoroughly to achieve a smooth, consistent texture. Proper ingredient selection and mixing help your machine run efficiently and last longer.

Select Fresh, Quality Ingredients

Choosing fresh, high-quality ingredients is essential for maximizing your ice cream machine’s lifespan. Ingredient freshness ensures your recipes turn out smoothly and prevent strain on the machine caused by inconsistent textures or excess moisture. Always prioritize quality assurance by sourcing ingredients from reputable suppliers or stores. Fresh dairy, ripe fruits, and premium flavorings reduce the risk of spoilage or contamination that can damage your equipment over time. Using high-quality ingredients also minimizes the need for excessive cleaning and maintenance, which can cause wear. Proper component maintenance, including inspecting and replacing parts as needed, can further prolong your machine’s life. Regularly monitoring engine performance and ensuring all components are functioning correctly can prevent unexpected breakdowns. Paying attention to ingredient storage and handling practices can also help maintain ingredient quality and prevent spoilage. Additionally, understanding the importance of security vulnerabilities in your supply chain can help protect your ingredients from contamination or theft. Focus on ingredient freshness and quality assurance to keep your ice cream machine in top shape.

Mix Thoroughly for Consistency

Ensuring your ingredients are well-mixed is key to achieving a smooth, consistent ice cream texture that minimizes stress on your machine. Proper mixing guarantees the right ingredient ratios and enhances flavor consistency. To do this effectively:

- Use a reliable recipe and follow precise measurements for each ingredient.

- Mix ingredients thoroughly until the mixture is uniform, avoiding lumps or streaks. Incorporating proper ingredient mixing techniques helps prevent inconsistencies and ensures an even distribution of flavors.

- Taste and adjust flavors before freezing to make sure consistency throughout the batch.

- Recognize that WWE Raw’s Financial Impact demonstrates how effective resource allocation and strategic planning can generate billions, similar to maximize space and organization for optimal results. Additionally, understanding the influence of astrological signs can help in creating a harmonious environment that supports your culinary endeavors, just as bike tire pressure optimization improves performance on gravel roads.

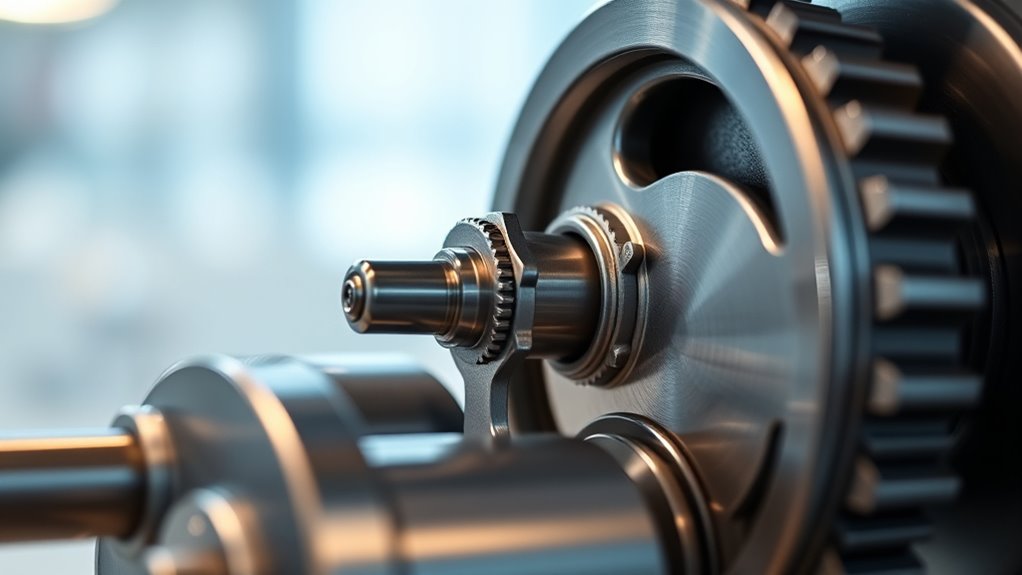

Keep the Machine’s Components Properly Lubricated

Regularly lubricating your ice cream machine’s moving parts is essential to keep it running smoothly. Follow a consistent lubrication schedule to prevent wear and tear on components like gears and chutes. Use high-quality oil suited for food equipment to guarantee safety and optimal performance. Low-quality or incorrect oils can cause buildup or damage, leading to costly repairs. Check manufacturer recommendations for lubrication intervals and oil type, and stick to them closely. Keep an eye on the condition of the lubricant—replace it if it appears dirty or degraded. Proper lubrication reduces friction, minimizes noise, and extends the life of your machine. Staying diligent with lubrication is a simple yet vital step in maintaining peak performance and avoiding unnecessary downtime. Additionally, understanding the Kia Tuning options can help improve your vehicle’s overall efficiency and longevity. Being aware of automation in business can also inspire innovative ways to optimize your maintenance routines and operational efficiency.

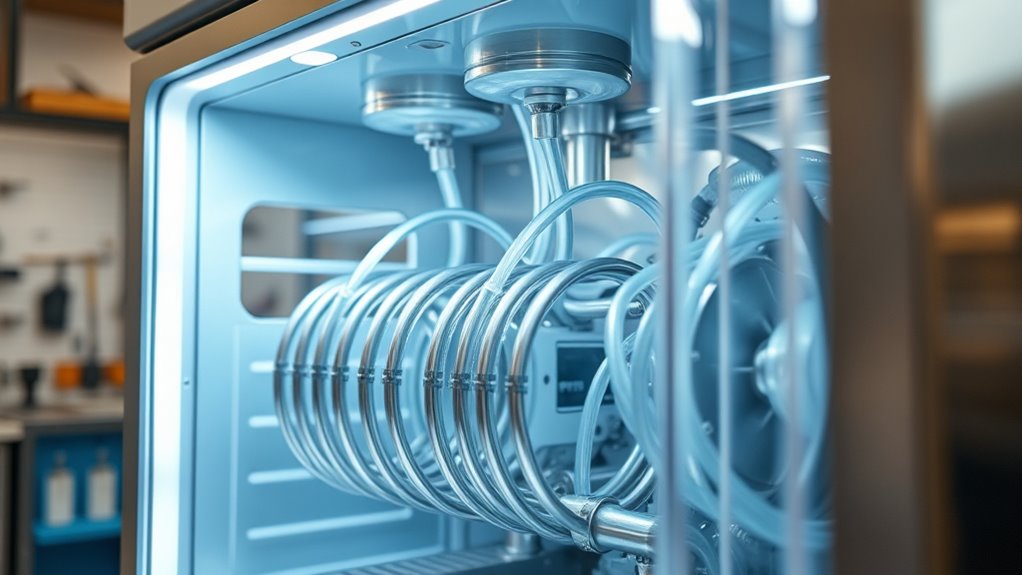

Monitor and Maintain the Refrigeration System

To keep your ice cream machine running smoothly, you need to regularly check your refrigerant levels and top them off if needed. Make sure to clean the condenser coils often to prevent overheating and maintain efficiency. Also, inspect the temperature settings to ensure they stay within the ideal range for quality and safety. Regular maintenance of the cooling system can help prevent performance issues and extend the lifespan of your machine. Additionally, monitoring ambient room temperature can help maintain consistent cooling performance and prevent unnecessary strain on the system. Implementing emotional support strategies for staff responsible for maintenance can improve overall equipment care and operational reliability. Ensuring proper cooling system maintenance can further optimize efficiency and prolong your equipment’s operational life. Incorporating predictive analytics can help detect potential system failures before they occur, further safeguarding your investment.

Check Refrigerant Levels Regularly

Since refrigerant levels directly impact your ice cream machine’s cooling efficiency, it’s essential to check them frequently. Regular refrigerant checks ensure your system runs smoothly and prevents costly breakdowns. To maintain ideal performance, follow these steps:

- Monitor refrigerant levels using a gauge to ensure they’re within the recommended range. Proper refrigerant levels are critical for optimal cooling and energy efficiency.

- Perform leak detection regularly to spot any refrigerant leaks early, which can compromise cooling. Utilizing Leak Detection Methods can help identify issues swiftly.

- Refill refrigerant if levels are low, but only after identifying and fixing the leak to avoid unnecessary loss.

- Incorporate efficient heat pump technology to enhance overall system performance and energy savings.

Clean Condenser Coils Often

Dirty condenser coils can substantially hinder your ice cream machine’s cooling performance, even if refrigerant levels are ideal. Regularly cleaning coils is vital to maintain efficient heat transfer and prevent strain on the compressor. During coil maintenance, turn off the machine and carefully remove dust, dirt, and debris from the coils using a brush or vacuum. Avoid damaging the fins while cleaning, as bent fins can reduce airflow. Well-maintained coils help your machine operate smoothly and extend its lifespan. Incorporating coil maintenance into your routine can prevent costly repairs and ensure peak cooling and energy efficiency. Neglecting this step can cause overheating and increased wear. Proper coil maintenance also supports personal finance management by reducing energy costs and preventing costly repairs. By keeping your condenser coils clean, you support reliable operation and help your ice cream machine last longer.

Inspect Temperature Settings

Regularly inspecting your ice cream machine’s temperature settings guarantees it stays within ideal ranges, preventing spoilage and equipment strain. To do this effectively, focus on three key steps:

- Check temperature calibration regularly to ensure the display matches actual temperatures, preventing inaccurate readings.

- Test sensor accuracy by using a reliable thermometer, verifying that the internal sensors reflect the true temperature.

- Adjust settings as needed to maintain consistent cooling, especially if you notice fluctuations or if the machine is running excessively.

Avoid Overloading the Machine During Operation

To keep your ice cream machine running smoothly, it’s crucial to avoid overloading it during operation. Overloading strains the motor and compressor, risking damage and costly repairs. When you overload the machine, it can also compromise operator safety by increasing the chance of jams or electrical issues. Additionally, an overloaded machine consumes more energy, reducing overall energy efficiency and increasing operational costs. To prevent these problems, always follow the manufacturer’s recommended capacity limits and avoid adding excessive ingredients at once. Monitor the mixture’s consistency and ensure you’re not pushing the machine beyond its designed workload. By respecting these guidelines, you help extend your machine’s lifespan, maintain a safe working environment, and optimize energy use for better efficiency.

Store Your Equipment in a Suitable Environment

You should store your ice cream machine in a cool, dry place away from direct sunlight. Keeping it out of humid areas prevents rust and electrical issues. Proper storage helps prolong your equipment’s lifespan and guarantees it functions smoothly when you need it.

Choose a Cool Location

Choosing a cool, stable environment for your ice cream machine is essential to extend its lifespan. A cool climate helps prevent overheating and reduces wear on components. To guarantee ideal placement, consider these tips:

- Select a shaded area away from direct sunlight, which can raise temperatures and stress the machine.

- Keep the environment well-ventilated to avoid heat buildup and improve airflow.

- Avoid placing the equipment near heat sources like ovens or radiators that can cause temperature fluctuations.

Keep Away From Humidity

Ensuring your ice cream machine stays in top condition means paying attention to the environment it’s stored in. Humidity control is vital because excess moisture can lead to mold growth and damage internal components. Store your equipment in a dry, well-ventilated space to prevent humidity buildup. Avoid areas prone to dampness or leaks, as these create ideal conditions for mold prevention issues. Regularly check the storage environment for moisture and use dehumidifiers if needed. Keeping your machine in a low-humidity setting not only extends its lifespan but also guarantees it operates efficiently. Proper humidity control reduces the risk of corrosion and mold, safeguarding your investment and ensuring your ice cream stays fresh and safe to consume.

Avoid Direct Sunlight

Avoiding direct sunlight is essential for preserving your ice cream machine’s condition. Sunlight exposure can cause sun damage, degrading parts and reducing efficiency over time. To protect your equipment, consider these tips:

- Place your machine in a shaded area or inside a cool, indoor space.

- Use curtains or blinds to block sunlight if it shines through windows.

- Regularly check for any signs of sun damage, such as fading or overheating.

Perform Routine Inspections and Replace Worn Parts

Regular inspections are essential to keep your ice cream machine running smoothly. You should regularly check for signs of wear, leaks, or any unusual noises to catch issues early. Adhering to a consistent cleaning schedule helps prevent buildup that can cause parts to degrade faster. During inspections, focus on identifying worn or damaged parts that may need replacement—such as seals, gaskets, or blades. Replacing worn parts promptly ensures peak performance and prevents costly breakdowns. Keep a log of inspections and repairs to track recurring issues and maintain an effective maintenance routine. By staying proactive with routine inspections and part replacement, you extend the lifespan of your machine, improve its efficiency, and reduce downtime, saving you time and money in the long run.

Follow Manufacturer Guidelines and Maintenance Schedules

Following the manufacturer’s guidelines and maintenance schedules is key to keeping your ice cream machine in top shape. Regularly adhering to recommended cleaning routines ensures ingredients stay fresh and prevent buildup that can affect quality. To maximize the machine’s lifespan, consider these steps:

- Schedule regular cleanings based on usage to maintain ingredient quality and prevent bacterial growth.

- Follow recommended lubrication and part replacements at specified intervals to avoid wear and tear.

- Inspect and calibrate settings periodically to ensure ideal performance and consistency.

Troubleshoot Common Issues Promptly

When your ice cream machine starts acting up, addressing issues promptly can prevent costly repairs and downtime. If you notice inconsistent ice cream texture or flavor fluctuations, don’t ignore the signs. Check the machine’s temperature settings first—improper temperatures can lead to ice crystal formation, affecting texture and taste. If the mixture isn’t freezing evenly, inspect the compressor and refrigeration system for blockages or malfunctions. A clogged or dirty condenser coil can also cause cooling issues. Listen for unusual noises or leaks, which may indicate mechanical problems. By troubleshooting these issues quickly, you can maintain smooth operation, ensuring your ice cream remains creamy and flavorful. Regularly monitoring performance allows you to catch minor problems before they escalate, extending the life of your machine.

Invest in Professional Servicing When Needed

If troubleshooting on your own doesn’t resolve persistent issues, bringing in a professional can save you time and prevent further damage. A skilled technician can perform essential tasks like calibration techniques to ensure your machine runs accurately and efficiently. They can also recommend and install accessory upgrades that enhance performance and extend lifespan. When scheduling professional servicing, consider these steps:

- Request a calibration check to optimize temperature controls.

- Ask about accessory upgrades that improve durability or ease maintenance.

- Ensure they perform thorough cleaning and inspect critical components for wear.

Investing in expert care helps catch problems early and keeps your ice cream machine running smoothly longer. Regular professional servicing is a smart move to maximize your equipment’s lifespan and maintain top-quality production.

Frequently Asked Questions

How Often Should I Replace the Machine’S Filters?

You should check your ice cream machine’s filter maintenance and follow a regular replacement schedule. Typically, filters need replacing every three to six months, depending on usage and water quality. Regularly inspect the filter for signs of clogging or wear, and don’t wait too long to replace it. Keeping up with the replacement schedule guarantees your machine runs efficiently and prevents buildup that can affect ice cream quality.

What Signs Indicate My Ice Cream Machine Needs Professional Servicing?

Imagine your ice cream machine as a well-tuned orchestra—when it starts making strange machine noise or shows inconsistent freezing, it’s like a discordant note. These signs indicate you need professional servicing before the problem worsens. Don’t ignore unusual sounds or melting inconsistencies. Addressing these issues promptly keeps your machine humming smoothly, preserving its sweet performance and extending its lifespan. Stay attentive, and your machine will serve up perfect treats for years.

Can I Use Homemade Cleaning Solutions Safely on the Equipment?

You might wonder if homemade cleaning solutions are safe for your ice cream machine. While some DIY cleaners can be effective, they may not guarantee equipment safety. Using homemade cleaning could leave residues or damage parts, risking contamination. Always check your manufacturer’s recommendations before trying homemade cleaning. For maximum equipment safety, stick to approved cleaning products designed for ice cream machines, ensuring thorough sanitation without compromising the machine’s integrity.

How Do Environmental Factors Affect My Machine’S Performance?

Many believe environmental factors don’t impact machines, but humidity control and ambient temperature actually play vital roles. High humidity can cause moisture buildup, leading to mold or corrosion, while extreme temperatures strain your equipment’s components. By maintaining proper humidity levels and keeping the ambient temperature stable, you guarantee your ice cream machine performs at its best, lasts longer, and produces better-quality ice cream. Don’t overlook these factors—they’re key to your machine’s health.

What Is the Ideal Temperature Range for Storage and Operation?

You should keep your ice cream machine at the ideal temperature range of 0°F to 10°F for maximum storage and operation. Proper temperature control ensures your machine runs efficiently and prevents spoilage. During use, maintain the same temperature to keep the ice cream consistently frozen and to avoid strain on the motor. Regularly monitor and adjust settings as needed to ensure your machine stays within this suitable storage and operational range.

Conclusion

By following these tips, you’ll keep your ice cream machine running smoothly like a well-oiled machine. Regular cleaning, proper maintenance, and prompt troubleshooting are your best tools to extend its lifespan. Think of your machine as a trusted friend—caring for it guarantees many delicious treats ahead. Stay attentive and proactive, and you’ll enjoy perfectly frozen desserts for years to come, just like savoring a sweet, lasting memory.