To avoid costly mistakes when installing your ice cream machine, choose a well-ventilated, high-traffic spot away from heat sources and direct sunlight. Guarantee your power supply matches the machine’s requirements and is properly grounded. Level and stabilize the unit with a bubble level, and connect water and drainage systems correctly to prevent leaks. Regularly check temperature, ventilation, and calibration settings. For smooth operation and long-term success, following these steps will set you up for ideal results.

Key Takeaways

- Choose a level, well-ventilated location away from heat sources for optimal machine performance.

- Ensure proper leveling and stable setup with a bubble level to prevent operational issues.

- Connect water and drainage systems securely, using filters and correct angles to avoid leaks and blockages.

- Use a dedicated power outlet with correct voltage, avoiding extension cords and following electrical safety standards.

- Perform routine checks and calibration to maintain temperature, stability, and product quality, preventing costly repairs.

Choosing the Right Location for Your Ice Cream Machine

Selecting the right location for your ice cream machine is essential to guarantee it operates efficiently and stays in good condition. You want a spot with enough space for easy access and maintenance, preventing overcrowding. Consider the visibility of your machine, as showcasing appealing ice cream flavors can attract customers and boost sales. Positioning it near high-traffic areas maximizes exposure and supports your marketing strategies. Keep the environment cool and well-ventilated to prevent overheating and ensure consistent performance. Avoid placing it too close to heat sources or direct sunlight, which could spoil the ice cream or cause operational issues. airflow management is crucial to maintain optimal temperature and prevent overheating of the machine. Proper professional setup ensures longevity and smooth operation of your equipment. Additionally, understanding RMD requirements can help you plan your maintenance schedule to avoid penalties and keep your machine running smoothly. To further enhance performance, consider implementing Hyundai Tuning techniques to optimize the electrical and mechanical systems of your equipment, ensuring reliable operation and durability.

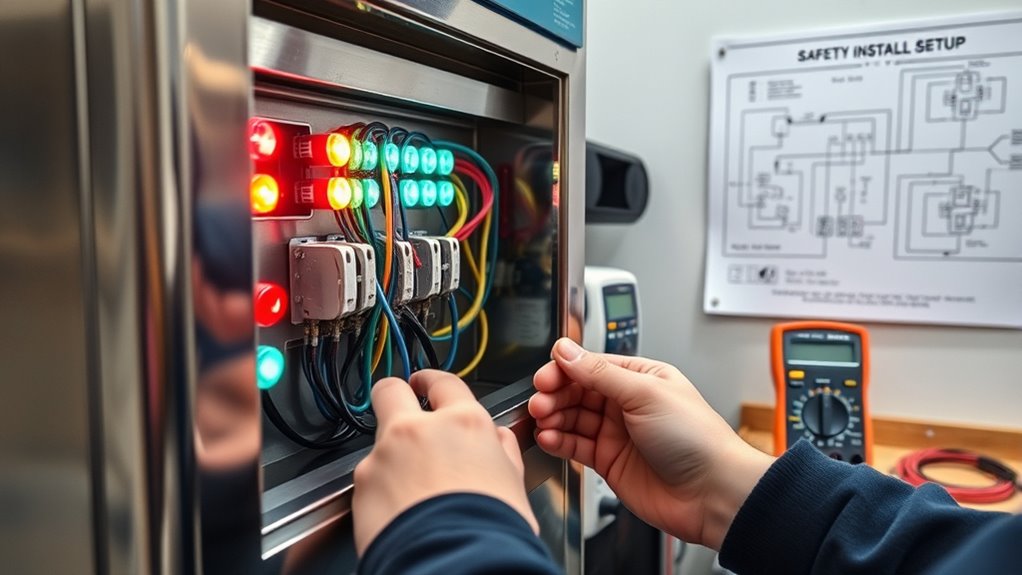

Ensuring Proper Power Supply and Electrical Setup

To keep your ice cream machine running smoothly, you need to guarantee it has the correct power source and electrical setup. Make sure the wiring meets safety standards and that the grounding is properly established to prevent electrical hazards. Addressing these points now helps avoid operational issues and keeps everyone safe.

Power Source Requirements

Ensuring your ice cream machine has the proper power supply is vital for safe and reliable operation. Check that the outlet matches the machine’s voltage and amperage requirements to prevent electrical issues. Using the correct power source helps maintain electrical safety by reducing the risk of shorts, overloads, or fires. Avoid using extension cords or adapting plugs, as these can compromise electrical safety and lead to power fluctuations. Verify that your circuit can handle the machine’s power load without tripping or causing instability. Properly rated circuits ensure consistent operation and protect your equipment. Always follow the manufacturer’s specifications for voltage, amperage, and dedicated circuits to prevent damage and guarantee safety during operation. Correct power source setup is a critical step for a successful installation. Understanding electrical safety is essential to prevent potential hazards and ensure your equipment functions correctly. Additionally, considering the electric power generation capabilities of related equipment can help optimize energy use and prevent overloads. Being aware of AI-driven solutions in healthcare can also inform better planning for electrical needs in advanced facilities. Properly managing power distribution within your setup can further enhance safety and efficiency.

Electrical Wiring Standards

Proper electrical wiring is essential to guarantee your ice cream machine operates safely and efficiently. You must follow wiring standards to prevent electrical faults and ensure consistent power delivery. Use correctly rated wires and connectors, adhering to local codes and manufacturer specifications. Grounding safety is critical; always connect the machine to a proper grounding system to minimize shock risks and protect equipment. Avoid makeshift wiring solutions that could cause short circuits or electrical fires. Check that all outlets and circuits can handle the machine’s power load without overload. Proper wiring reduces downtime and maintenance costs, ensuring your machine runs smoothly. Additionally, choosing appropriate crochet styles for locs can help protect wiring and cords from damage over time. Being aware of electrical safety guidelines is crucial to prevent hazards and ensure a reliable setup. Following these standards also helps in compliance with electrical codes, which is vital for legal and safety reasons. Remember, following established wiring standards isn’t optional—it’s crucial for safety, performance, and compliance. Paying attention to proper installation procedures can further enhance safety and longevity of your equipment.

Safety Grounding Practices

Effective electrical wiring starts with solid safety grounding practices. Proper grounding procedures prevent electrical shock and protect your ice cream machine from damage. Always ensure the equipment is connected to a grounded outlet that complies with local electrical safety codes. Use a grounding rod or grounding wire if necessary, and verify connections are secure. Remember, a well-grounded setup minimizes the risk of short circuits and electrical faults. Proper grounding not only enhances safety but also aligns with established newborn safety guidelines, helping to prevent potential hazards. Additionally, following manufacturer instructions for grounding can prevent electrical fires and ensure compliance with safety standards. Incorporating sound engineering principles during installation can further reduce risks and improve overall electrical safety. Understanding the contrast ratio can also influence the effectiveness of safety indicators in electrical systems, ensuring clear visual cues for grounding issues. Here’s a quick overview:

| Grounding Point | Importance |

|---|---|

| Grounded Outlet | Ensures safe power connection |

| Grounding Wire | Provides a clear path to earth |

| Grounding Rod | Limits electrical faults within the system |

| Proper Connection Points | Prevents accidental disconnection |

| Regular Inspection | Maintains ongoing electrical safety |

Prioritize grounding procedures to ensure safe operation and avoid costly mistakes.

Leveling and Stabilizing the Equipment

Before installing your ice cream machine, it’s essential to make sure it’s level and stable. An uneven setup can cause vibrations, affecting the ice cream flavor and consistency, and may lead to malfunctions. Use a bubble level to check the machine’s position from multiple angles. Adjust the leveling feet until the machine sits perfectly flat. Stabilizing the equipment prevents wobbling, which can affect performance and generate noise that customers notice. Proper leveling ensures the compressor and internal components operate smoothly, extending the machine’s lifespan. Additionally, appliance maintenance plans in place can help identify and address leveling issues early. Regularly inspecting for vibrations can prevent further damage and ensure consistent operation. Recognizing trust issues in the setup process can help prevent misalignments that undermine stability. Take the time to double-check the setup before powering on—this small step saves you from costly repairs and guarantees a seamless operation.

Correctly Connecting Water and Drainage Systems

Once your ice cream machine is level and stable, connecting the water and drainage systems correctly becomes the next essential step. Proper setup guarantees ideal operation and prevents costly repairs. Start by attaching the water supply line to suitable plumbing fixtures, ensuring a secure fit and proper water filtration to maintain ice quality. For drainage, connect the drain line securely to an appropriate outlet, preventing leaks or blockages. Keep these tips in mind:

Ensure secure, leak-proof water and drain connections for smooth, trouble-free ice cream machine operation.

- Use quality plumbing fixtures to avoid leaks

- Install water filtration to ensure clean water

- Check for secure, watertight connections

- Keep drain lines angled for proper flow

- Avoid kinks or bends in water and drain hoses

- Ensure proper water filtration to keep ice quality high and prevent contamination

Following these steps guarantees efficient water flow and drainage, helping your ice cream machine run smoothly.

Verifying Temperature and Ventilation Requirements

To guarantee your ice cream machine operates efficiently and safely, you need to verify that the installation site meets the required temperature and ventilation standards. Proper temperature control is vital to prevent overheating and ensure consistent product quality. Check that the room temperature stays within the manufacturer’s recommended range, usually between 70-75°F (21-24°C). Additionally, ventilation requirements must be met to prevent heat buildup around the machine. Ensure adequate airflow and exhaust systems are in place, especially if the machine generates heat or uses refrigeration components that emit warm air. Proper ventilation not only maintains ideal temperature control but also reduces the risk of moisture buildup and mechanical issues. Meeting these standards is essential for safe operation and long-term reliability of your ice cream machine. Regularly monitoring air quality features can help maintain optimal operating conditions, including air circulation and humidity levels. Implementing AI-powered monitoring systems can further enhance the accuracy and efficiency of environmental control, preventing costly mistakes.

Properly Assembling and Securing Components

Make sure you tighten all connections securely to prevent leaks and guarantee proper operation. Next, check that the machine is level so it functions smoothly and maintains consistent ice cream quality. Proper assembly now sets the foundation for safe and efficient use of your ice cream machine.

Tighten All Connections

Ensuring all connections are tightened properly is essential for the ice cream machine to operate smoothly and safely. An incomplete or loose connection can cause leaks, malfunctions, or damage. As part of your installation checklist, double-check each connection to prevent future connection troubleshooting issues. Use a wrench or suitable tool to tighten fittings securely, but avoid overtightening, which can damage components. Here are key points to focus on:

- Verify all water and power connections are snug.

- Ensure hoses are properly attached without kinks.

- Confirm fittings are tightened evenly.

- Check for leaks after initial startup.

- Revisit connections if you notice irregular operation.

Proper tightening reduces risks and guarantees your machine functions efficiently from the start.

Level the Equipment Properly

After tightening all connections, it’s important to verify that your ice cream machine is level. Use a spirit level to ensure the unit sits evenly on the surface; an unlevel machine can cause uneven mixing and poor product quality. Properly leveling the equipment helps maintain consistent operation, reducing the risk of malfunctions. Once level, securely secure all components to prevent movement during use. Regularly follow cleaning protocols to prevent buildup that can affect balance and performance. Incorporate routine maintenance schedules to check for shifting or wobbling over time, especially after cleaning or relocations. Proper leveling not only prolongs your machine’s lifespan but also guarantees optimal ice cream quality and efficiency. Taking these steps helps avoid costly repairs and preserves your investment.

Calibrating Settings for Optimal Performance

To achieve the best ice cream quality, you need to calibrate your machine’s settings carefully. Proper calibration ensures consistent texture, flavor customization, and customer satisfaction. Start by adjusting the mix temperature to maintain smoothness and prevent overrun issues. Next, fine-tune the freezing cycle to optimize consistency and reduce waste. Consider the agitation speed to balance creaminess and production speed. Use customer feedback to identify flavor preferences and tweak the flavoring levels accordingly. Also, regularly check the compressor and refrigerant settings to avoid temperature fluctuations. Keep these key points in mind:

- Adjust mix temperature for smooth texture

- Fine-tune freezing cycle for consistency

- Optimize agitation speed

- Incorporate customer feedback for flavor

- Monitor compressor and refrigerant settings

Implementing Maintenance Access and Safety Measures

Implementing maintenance access and safety measures is essential for keeping your ice cream machine running smoothly and preventing accidents. Guarantee easy access points for cleaning procedures, such as removable panels or hinged doors, so you can maintain hygiene and efficiency. Clear pathways around the machine help prevent tripping hazards and facilitate quick maintenance. Always follow safety protocols, like disconnecting power before servicing, to protect yourself and staff. Keep safety signs visible and ensure emergency shut-offs are within reach. Regularly inspecting safety features and access points minimizes risks and promotes customer safety. Proper maintenance access makes cleaning and repairs straightforward, reducing downtime and costly mistakes. Prioritizing these safety measures safeguards your staff, customers, and your investment in the long run.

Testing the Machine Before Full Operation

Before you start full operation, make sure the power supply is properly connected and functioning. Run a few trial cycles to identify any issues and ensure everything runs smoothly. Finally, check the ice cream’s consistency and texture to confirm the machine is working at ideal quality.

Verify Power Supply Properly

Ensuring the power supply is properly connected and functioning is a vital step before operating your ice cream machine. First, check that the power outlet matches the machine’s voltage requirements to prevent damage. Confirm the plug is securely inserted into the outlet, and inspect the cord for any damage. Use a voltage tester if needed to verify voltage compatibility. Here are some key points to consider:

- Make certain the power outlet supplies the correct voltage

- Avoid using extension cords that can’t handle the load

- Check that the power cord is undamaged and properly connected

- Confirm the circuit breaker is ON and functioning

- Test the outlet with a multimeter for voltage accuracy

Taking these steps helps prevent electrical issues and ensures safe operation.

Conduct Trial Runs Carefully

Once you’ve confirmed that the power supply is properly connected and functioning, it’s important to conduct a trial run of your ice cream machine. This helps identify potential issues before serving customers. During testing, follow proper cleaning protocols to prevent contamination and ensure quality. Monitor how the machine operates, paying attention to noise, temperature, and consistency. Use the table below to guide your trial process:

| Step | Action | Purpose |

|---|---|---|

| Pre-run checks | Verify cleaning protocols | Prevent contamination |

| Start machine | Run for 10-15 minutes | Test functionality |

| Observe output | Check texture and flow | Ensure customer experience quality |

| Final assessment | Confirm smooth operation | Ready for service |

Careful trial runs help you deliver a reliable product and a positive customer experience.

Check Consistency and Texture

To verify that your ice cream machine produces the desired consistency and texture, you should carefully examine the output during the trial run. Focus on guaranteeing flavor consistency and texture stability across multiple servings. During testing, observe how smoothly the ice cream dispenses and whether it maintains a uniform texture. If the texture is too icy or too soft, adjustments may be needed. Also, check for any signs of separation or inconsistent flavor distribution.

Here are key points to contemplate:

- Confirm the ice cream is creamy and smooth

- Ensure flavor remains consistent throughout

- Check for any ice crystal formation

- Verify the texture is stable from start to finish

- Make adjustments if texture or flavor varies

Training Staff on Proper Usage and Troubleshooting

Training staff effectively on proper usage and troubleshooting is essential to keep the ice cream machine running smoothly and minimize downtime. Well-trained staff understand the machine’s functions and can quickly address common issues using troubleshooting techniques. Start by providing thorough staff training that covers daily operation procedures, cleaning protocols, and safety guidelines. Confirm your team knows how to identify signs of problems early and apply troubleshooting techniques confidently. Regular refresher sessions help reinforce knowledge and keep everyone up to date with new features or procedures. Clear documentation, such as quick-reference guides, can support ongoing troubleshooting. When staff are equipped with the right skills and knowledge, they can maintain peak performance, reduce service interruptions, and keep your ice cream operation profitable.

Frequently Asked Questions

How Often Should I Perform Routine Maintenance on My Ice Cream Machine?

You should perform routine maintenance on your ice cream machine regularly to guarantee peak performance. Follow your cleaning schedules diligently, ideally daily or after each use, to prevent buildup and contamination. Also, incorporate calibration tips to keep the machine running accurately and efficiently. Regular maintenance helps avoid costly repairs and ensures your ice cream always tastes great. Don’t neglect these steps, and you’ll keep your machine in top shape for years to come.

What Are Common Signs of Electrical Issues in Ice Cream Machines?

Imagine your ice cream machine humming smoothly, then suddenly flickering or stalling—that’s a sign of electrical faults. You might notice inconsistent freezing or strange noises, which hint at power fluctuations. Flickering lights or tripped circuit breakers also signal electrical issues. Stay alert to these signs, as they indicate potential electrical faults that could damage your machine. Addressing these problems early keeps your machine running efficiently and prevents costly repairs.

How Do I Prevent Mold and Bacteria Buildup Inside the Machine?

To prevent mold and bacteria buildup inside your ice cream machine, you should follow strict cleaning schedules and use sanitizer regularly. Make sure to thoroughly clean all parts that come into contact with ice cream, including the dispensing area and internal components. Using the right sanitizer guarantees bacteria are eliminated effectively. Consistent maintenance not only keeps your machine hygienic but also improves the quality and safety of your ice cream.

What Safety Equipment Is Recommended During Installation and Maintenance?

During installation and maintenance, you should wear protective gear like gloves and safety goggles to prevent injuries. It’s also essential to have emergency preparedness measures in place, such as a fire extinguisher nearby and knowledge of electrical safety. Always follow safety protocols, make certain of proper ventilation, and disconnect the power before working on the machine. These steps help keep you safe and prevent accidents during maintenance or installation.

How Can I Extend the Lifespan of My Ice Cream Machine?

To extend your ice cream machine’s lifespan, focus on proper cleaning regularly to prevent buildup and guarantee ideal performance. Additionally, replace worn or damaged parts promptly to avoid further damage. Keep an eye on the machine’s operation, and address issues early. Maintaining a consistent cleaning schedule and timely parts replacement help your machine stay in top shape, reducing costly repairs and prolonging its service life.

Conclusion

Think of your ice cream machine as a delicate garden. With the right location, proper care, and regular maintenance, it’ll flourish and serve up sweet success. Neglect the basics, and it’s like ignoring the watering schedule — problems will sprout. But when you follow these steps, your machine will thrive, producing perfect treats day after day. Keep nurturing it, and watch your ice cream business blossom into a sweet, worry-free paradise.